3D printed knee replacement: As medical technology continues to advance at a rapid pace, one area that has seen significant innovation is knee replacement surgery. Knee replacement surgery has come a long way in recent years, thanks to remarkable advancements in medical technology. Traditionally, knee replacements have involved using off-the-shelf implants that are sized to fit the patient’s anatomy as closely as possible. However, recent advancements in the field have introduced custom implants and 3d printed knee replacement, revolutionizing the way knee replacement surgeries are performed. These innovations have the potential to provide patients with better outcomes, shorter recovery times, and improved overall quality of life and not only improve the effectiveness of the procedure but can also make it more accessible and tailored to individual patient needs.

In this article, we will explore two groundbreaking innovations in knee replacement: custom implants and 3d printed knee replacement. For patients considering knee replacement surgery, these innovations open up exciting possibilities and can significantly impact their quality of life.

Table of Contents

ToggleThe Evolution of Knee Replacement Surgery

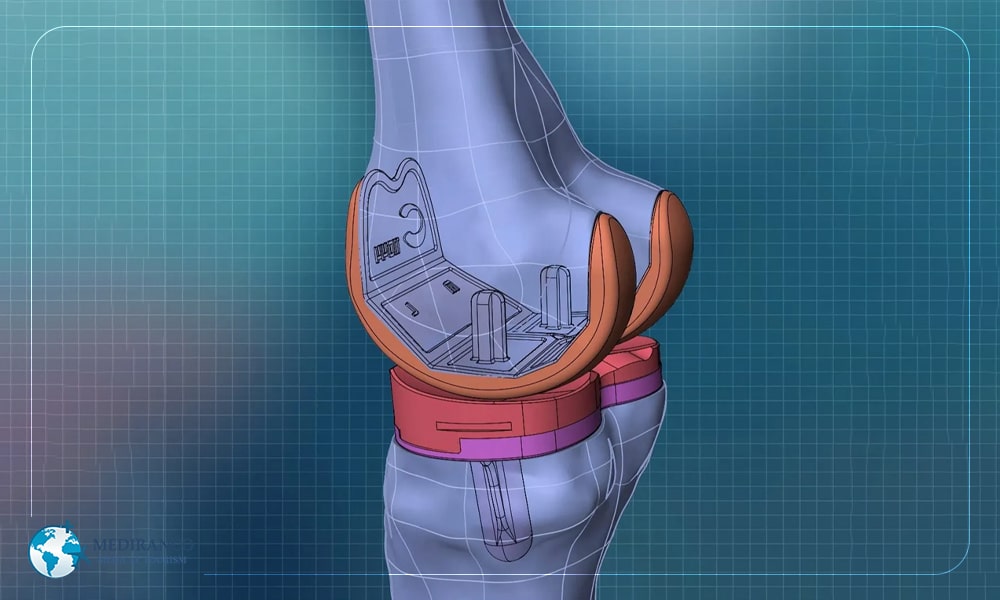

Knee replacement surgery, also known as knee arthroplasty, has been a game-changer for countless individuals suffering from chronic knee pain, arthritis, or injuries. It involves the removal of damaged or diseased knee joint components and their replacement with artificial prosthetic implants. Traditionally, these implants came in standard sizes and shapes, which, while effective for many patients, didn’t always provide an ideal fit.

Custom knee replacement: a tailored solution

Traditional knee replacement procedures involve using standard implants that come in a range of sizes. Surgeons select the implant size that most closely matches the patient’s anatomy. However, even with the best fitting implant, there can still be some amount of compromise in terms of fit and alignment. Unlike traditional off-the-shelf implants, custom implants are designed specifically for each patient, taking into account their unique anatomy and needs. Here’s how it works:

- Advanced Imaging: To create a custom implant, the surgeon begins by obtaining detailed 3D images of the patient’s knee joint. This can be done through CT scans or MRI scans, providing a precise map of the patient’s knee.

- Computer-Aided Design (CAD): Using specialized software, surgeons and engineers work together to design a custom implant that perfectly matches the patient’s knee anatomy. This includes the shape, size, and alignment of the implant.

- 3D Printing: Once the design is finalized, cutting-edge 3D printing technology is employed to create the custom implant. This process involves layer-by-layer deposition of biocompatible materials, resulting in a precise and patient-specific prosthetic.

- Surgical Precision: During the surgery, the surgeon can fit the custom implant with remarkable accuracy, reducing the risk of complications and improving overall outcomes.

Benefits of Custom knee replacement

Custom implants offer several key advantages for patients:

- Improved Fit: Custom implants provide a better fit, reducing the chances of implant-related complications and increasing the longevity of the implant.

- Reduced Pain: A better fit often means less pain and discomfort, leading to a faster and smoother recovery.

- Enhanced Functionality: Custom implants can help restore a patient’s knee function more effectively, allowing for a more active and pain-free lifestyle.

- Long-Term Benefits: With a custom implant, patients are more likely to enjoy the benefits of knee replacement for years to come.

3D printed knee replacement: A Revolution in Implant Manufacturing

Another innovation that has revolutionized knee replacement surgery is the use of 3D printing. 3D printing, also known as additive manufacturing, involves creating a three-dimensional object layer by layer, based on a digital model.

By applying 3D printing technology to knee replacement surgery, surgeons can create patient-specific instruments and implants with a level of precision that was previously unattainable.

1. Complex Geometries: 3D printing allows for the creation of complex implant geometries that were previously impossible with traditional manufacturing methods. This means that implants can be designed to mimic the natural shape and function of the knee joint more closely.

2. Material Selection: 3D printing offers flexibility in choosing materials for implants. Surgeons can select materials that are not only biocompatible but also optimized for strength and durability.

3. Rapid Prototyping: 3D printing enables rapid prototyping, allowing surgeons and engineers to refine implant designs quickly, leading to better outcomes for patients.

4. Personalization: Just like custom implants, 3D printing can be used to create implants tailored to an individual patient’s needs, ensuring a precise fit.

Benefits of 3D printed knee replacement

Patients stand to gain significantly from the integration of 3D printing in knee replacement surgery:

- Enhanced Customization: 3D printing enables a higher level of customization, resulting in implants that are uniquely suited to each patient.

- Shorter Surgery Times: The precision of 3D-printed implants often translates to shorter surgery times, reducing the time patients spend under anesthesia.

- Faster Recovery: The improved fit and reduced trauma associated with 3D-printed implants can lead to faster post-operative recovery.

- Long-Term Success: Patients can expect a greater likelihood of long-term success and fewer revision surgeries with 3D-printed implants.

- Additionally, 3D printing enables faster production times and reduces costs. Implants can be swiftly manufactured using the 3D printing process, eliminating the need for lengthy lead times associated with traditional manufacturing methods. This efficiency not only benefits the patient but also contributes to the overall cost-effectiveness of knee replacement surgeries.

The Future of Knee Replacement Surgery

The advancements in knee replacement surgery, specifically custom implants and 3D printing, hold immense potential for the future. As technology continues to evolve, further innovations can be expected in this field.

One area of ongoing research is the development of bioactive implants. These implants have the ability to promote tissue regeneration and integration, allowing for a more natural and long-lasting knee joint replacement. This could significantly improve patient outcomes, reduce the need for revision surgeries, and enhance the overall quality of life for knee replacement patients.

Additionally, advancements in materials science may lead to the development of more durable and biocompatible materials for knee implants. This would further enhance the longevity and performance of knee replacement implants, leading to improved patient satisfaction and reduced revision rates.

Medical Tourism and Access to Innovation

The rise of medical tourism has made it easier for patients to access these cutting-edge innovations in knee replacement surgery. Traveling abroad for medical procedures can be a cost-effective and convenient way to benefit from the latest advancements in healthcare.

- Cost Savings: Many countries with robust medical tourism industries offer high-quality care at a fraction of the cost of the same procedures in more developed nations. Patients can access custom implants and 3D printing technology without breaking the bank.

- Quality of Care: Leading medical tourism destinations often have state-of-the-art facilities and highly skilled surgeons, ensuring that patients receive world-class care.

- Personalized Treatment: Medical tourism destinations understand the importance of catering to international patients. This means that the process of obtaining custom implants or 3D-printed implants is streamlined for patients traveling from abroad.

- Cultural Experience: Combining medical treatment with a cultural experience can make the healing process more enjoyable. Patients can explore new destinations and cultures while receiving top-notch medical care.

Innovations in knee replacement surgery, such as custom implants and 3D Knee Replacement, have revolutionized the field, offering patients the promise of better outcomes, reduced pain, and faster recovery times. For individuals considering knee replacement surgery, medical tourism can provide access to these cutting-edge technologies at a fraction of the cost, all while enjoying a unique cultural experience. Whether you’re seeking a custom implant or a 3D Knee Replacement solution, the future of knee replacement is bright, and the possibilities are endless.

Cost of knee replacement in Iran

In some bordering countries, like Turkey, knee replacement procedure would cost less than 6,000 dollars. the cost of a total Knee Replacement in Iran , ranges from only $2,800 to $3,800.